Linear Bearings from Automotion Components

A linear bearing, also known as a linear ball bush or bushing, is a bearing that runs on a hardened linear shaft to help guide or support the movement of a component in a linear fashion. A cost effective method of achieving linear motion where the loads are light enough to not need conventional linear guides or where the guide can only be supported at the ends and not over the entire length.

As specialists in linear motion systems we offer you a choice of materials and sizes. So whether you need lightweight aluminium rails for use in aviation applications or stainless steel components for when exposure to water or corrosive chemicals is a factor, our knowledgable technical engineers are always on hand to provide assistance.

Make sure you download a free Linear Motion Handbook here and utilise our free CAD to help you save time planning your projects.

A linear bearing, also known as a linear ball bush or bushing, is a bearing that runs on a hardened linear shaft to help guide or support the movement of a component in a linear fashion. A cost effective method of achieving linear motion where the loads are light enough to not need conventional linear guides or where the guide can only be supported at the ends and not over the entire length.

As specialists in linear motion systems we offer you a choice of materials and sizes. So whether you need lightweight aluminium rails for use in aviation applications or stainless steel components for when exposure to water or corrosive chemicals is a factor, our knowledgable technical engineers are always on hand to provide assistance.

Make sure you download a free Linear Motion Handbook here and utilise our free CAD to help you save time planning your projects.

Linear Bearing Options

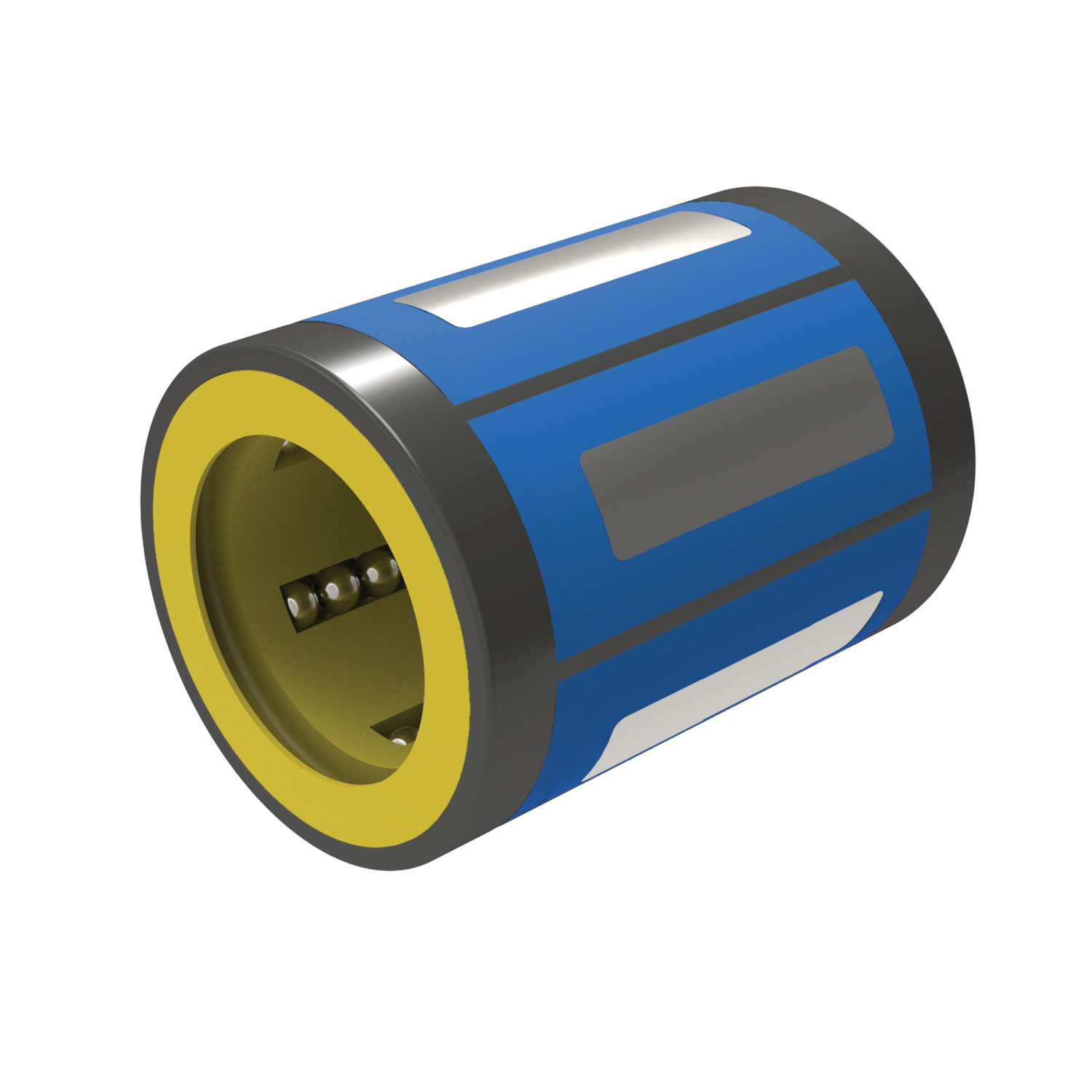

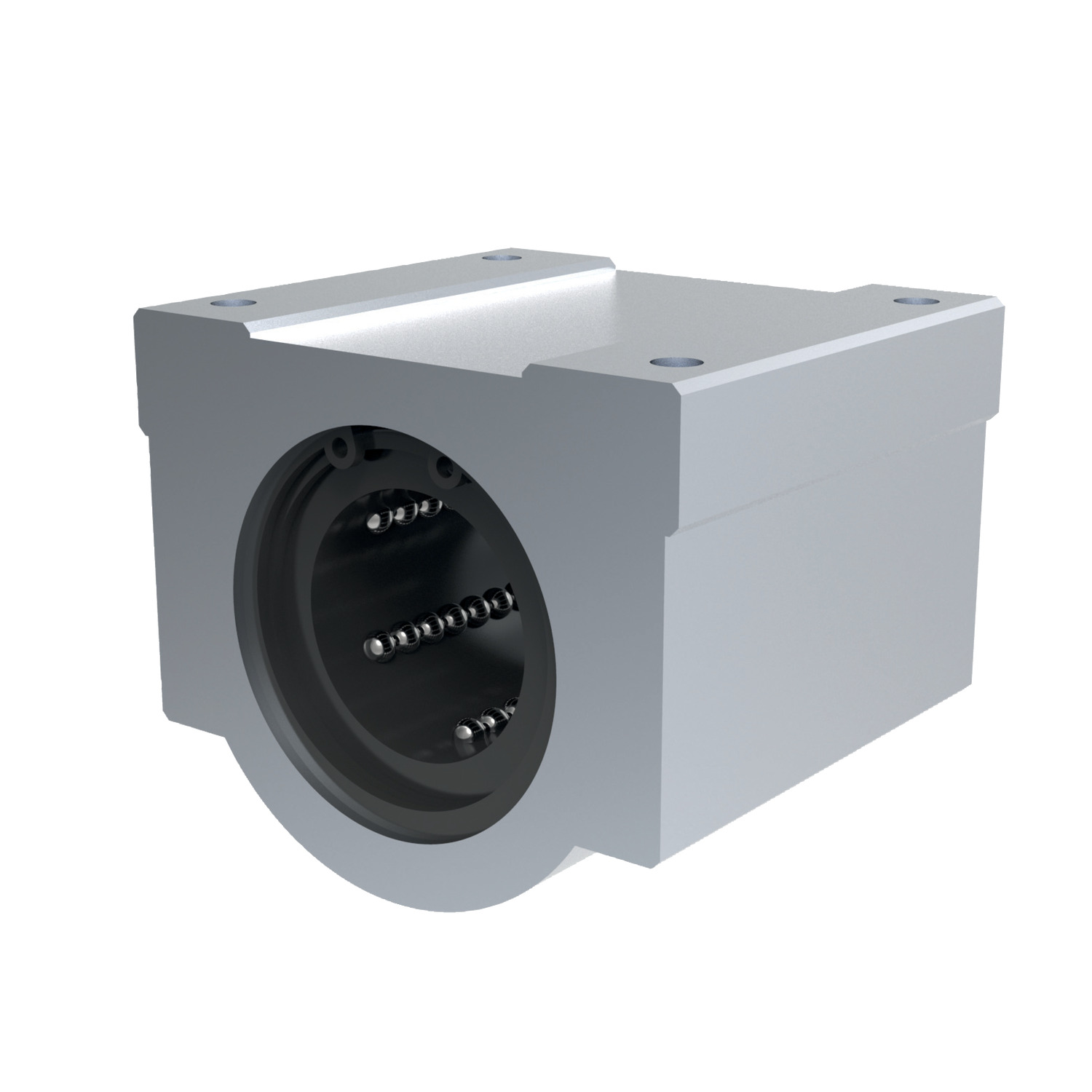

Closed Ball Bushings

Hardened and ground bearing steel body.

Single body resin reatainer. With nitrile rubber end seals.

Steel ball retainer available for higher temperature applications, with no end seals.

For use with hardened shafts only.

Nickel plated version on request. Stainless steel version also available.

Stainless steel (440C) with resin retainer.

With nitrile rubber end seals.

For use with corrosion resistant hardened shafts.

Double length. Hardened and ground bearing steel body.

With nitrile rubber eand seals.

For use with hardened steel shaft only.

Nickel plated version on request. Stainless steel version also available.

Duarble plastic body with corrosion resistant hardened steel raceway segments.

Low cost. Compact.

Oil resistant seal.

For use with hardened shaft only.

Hardened and ground steel ball plate from bearing steel.

Offers self-alignment, prolonging travel life by reducing friction.

For use with hardened shafts only.

Aluminium with aluminium-oxide ceramic coating.

Available with or without seals.

Can be run on hardened or soft steel shafts.

Standard or self-aligning.

Aluminium with aluminium-oxide ceramic coating.

Self-lubricating.

With or without seals.

Can be run on hardened or soft steel shafts.

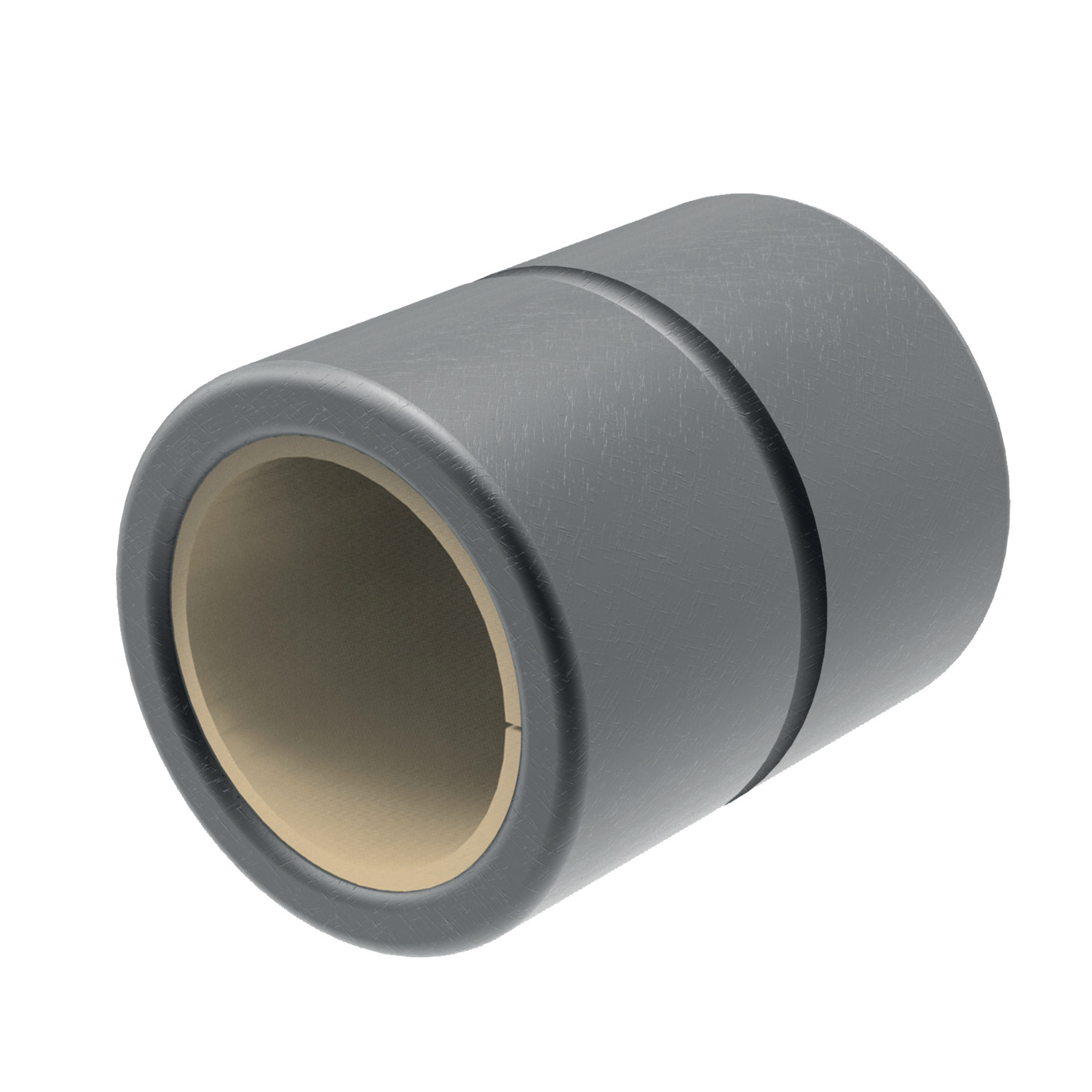

Open Ball Bushings

Hardened and ground bearing steel body.

SIngle body retainer.

WIth nitrile rubber eand seals.

Steel ball retainers available for higher temeperature applications, with no end seals.

For use with hardened shafts only.

With resin or stainless steel retainer.

With nitrile rubber end seals.

For use with corrosion resistant hardened shafts.

Nickel plated steel body. Hardened and ground.

Stainless steel ball.

Supplied with nitrile rubber end seals.

For use with hardened shafts only.

Aluminium, with aluminium-oxide ceramic coating.

Self-lubricating.

Can be run on hardened or soft steel shafts.

Flanged Ball Bushings

Circular flange. Hardened and ground bearing steel body.

Single body resin retainer.

Steel ball retainers available for higher temperature applications with no end seals.

For use with hardened shafts only.

Nickel plated version on request.

Square flange. Hardened and ground bearing steel body.

Single body resin retainer.

Steel ball retainers available for higher temperature applications with no end seals.

For use with hardened shafts only.

Nickel plated version on request.

Stainless steel.

Circular flange.

With nitrile rubber end seals.

For use with corrosion resistant hardened shafts.

Long Flanged Ball Bushings

Circular flange. Hardened and ground bearing steel body.

Single body resin retainer.

Steel ball retainers available for higher temperature applications with no end seals.

For use with hardened shafts only.

Nickel plated version on request.

Double complement. Hardened and ground bearing steel body. Single body resin retainer.

Steel ball retainers available for higher temperature applications with no end seals.

For use with hardened shafts only.

Nickel plated version on request.

Stainless steel.

Double complement.

With nitrile rubber end seals.

For use with corrosion resistant end seals.

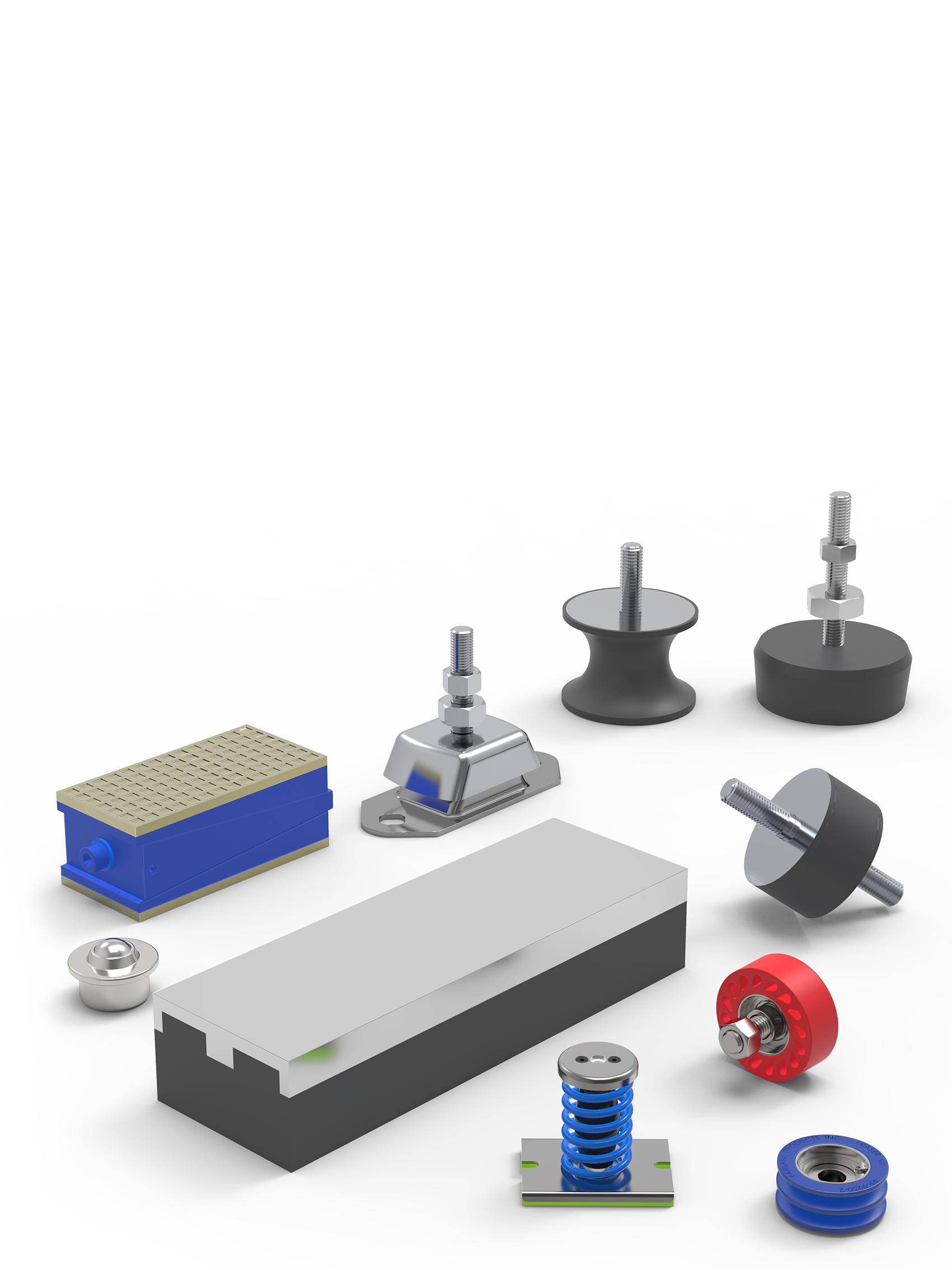

Associated Products

Steel Linear Shafts

Hard Stainless Shaft - L1772 - corrosion resistant hardened stainless steel 440C.

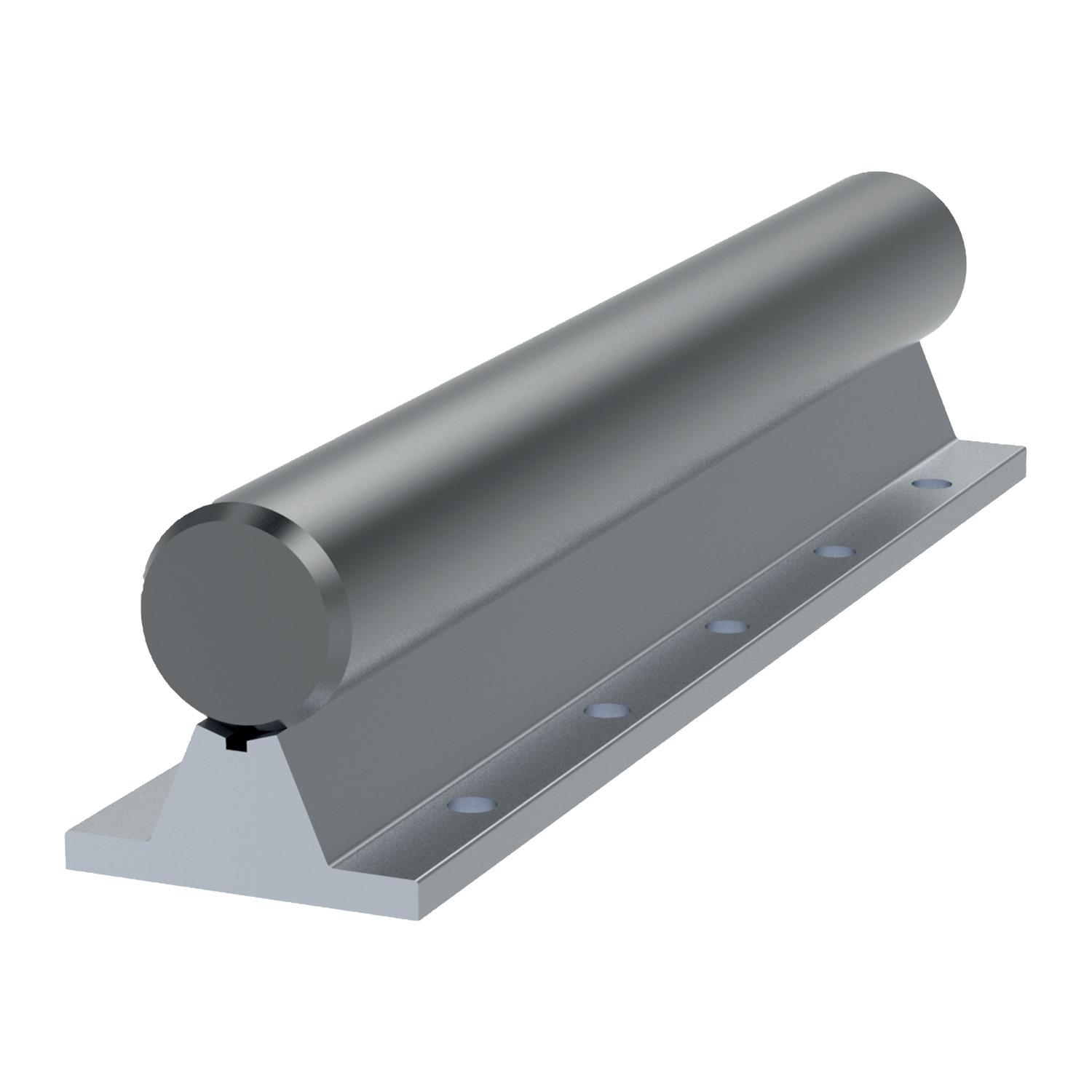

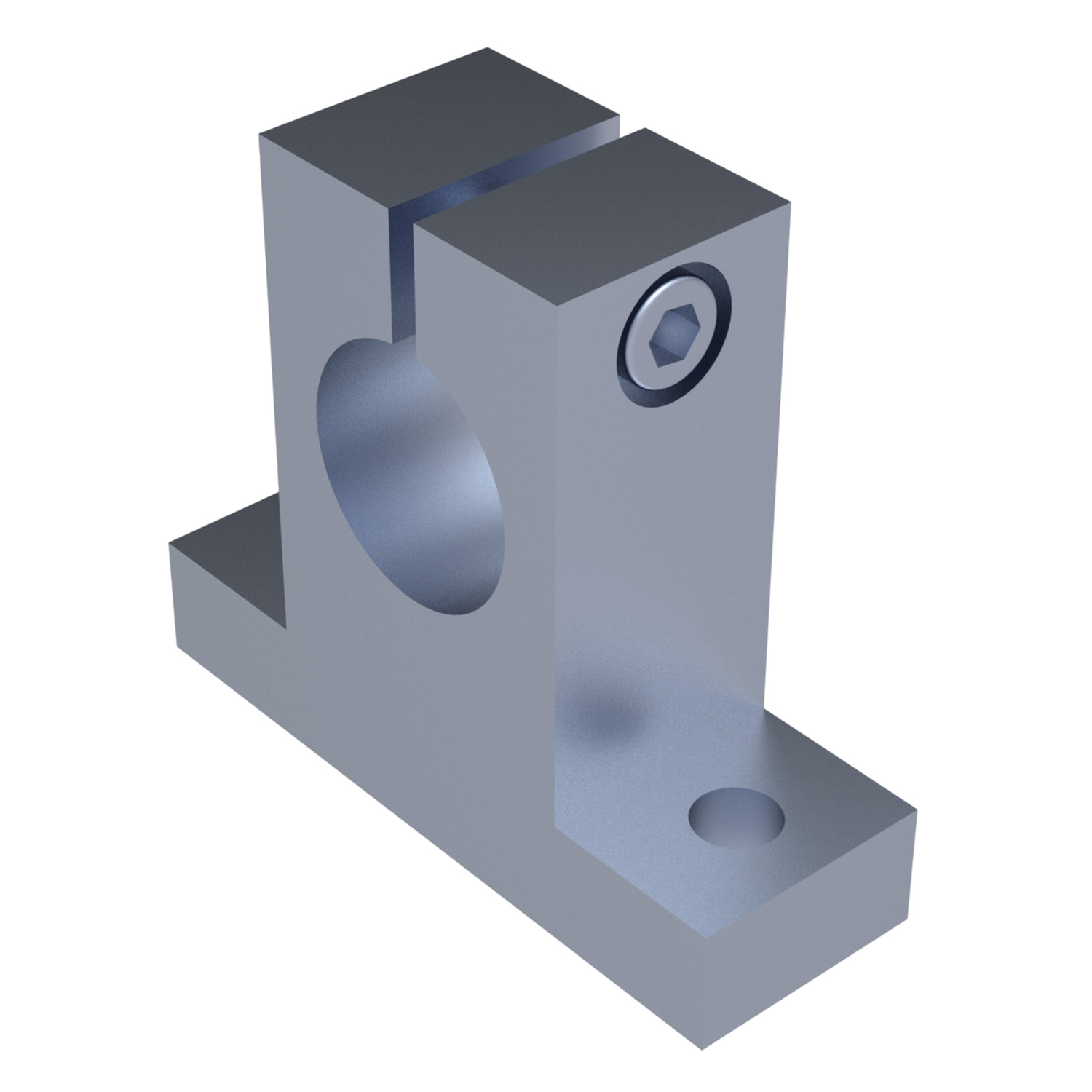

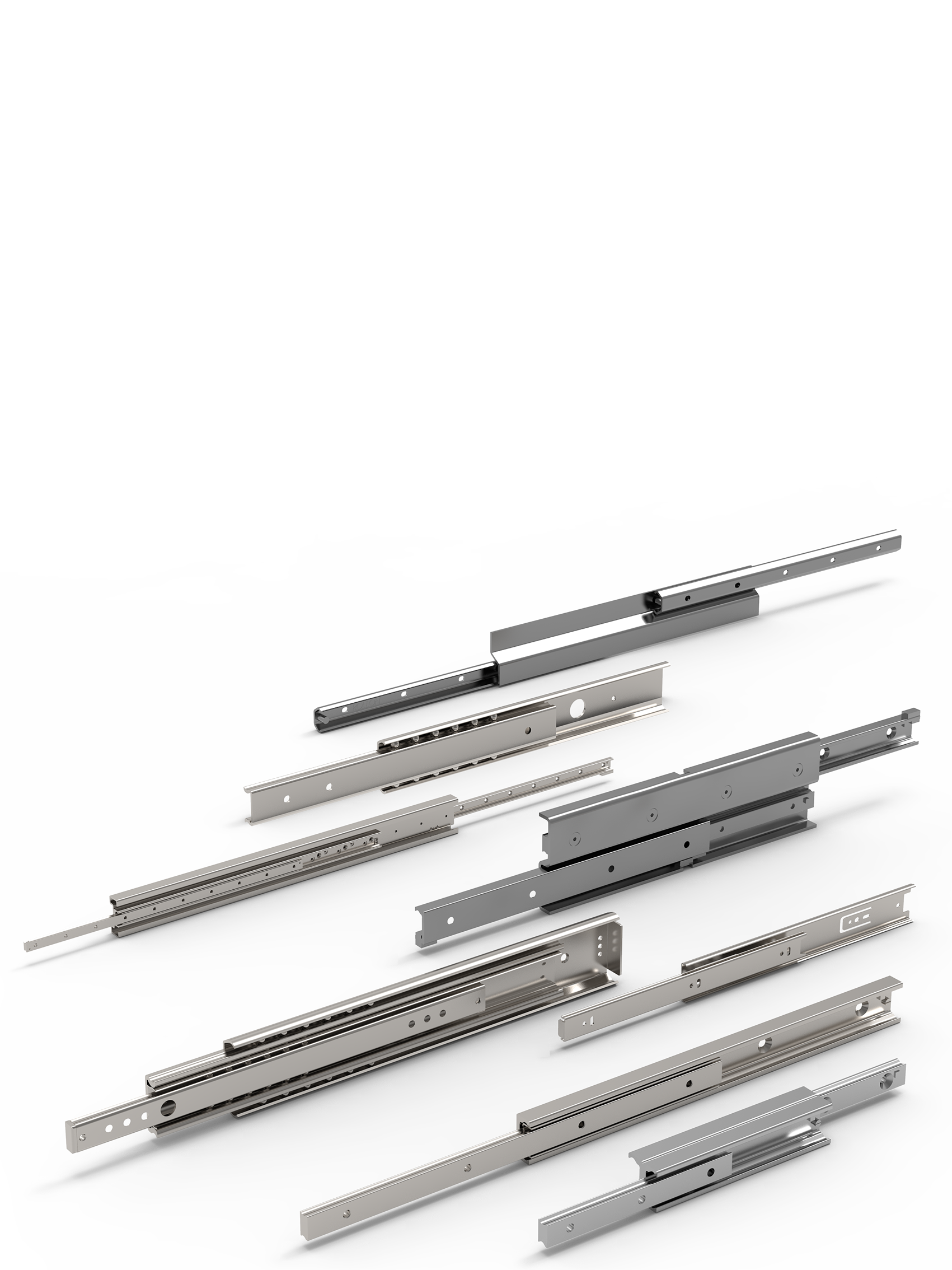

Linear Shaft Supports and Shaft End Supports

Shaft Support Rail - 12mm diameter to 80mm diameter up to 6 metre long.

Shaft End Supports - for shafts from 8mm to 40mm diameter.

Linear Carriages

Closed.

Aluminium body with linear bearing .

Resin retainer. Nitrile rubber end seals.

For use with hardened shafts only.

Unflanged.

Aluminium body, with steel shell linear bearing installed. Bearing has a resin retainer .

Supplied with nitrile rubber end seals.

Particularly effective for high loads and long stroke applications.

Open.

Aluminium carriage housing with stainless steel linear bushing installed.

Resin retainer and nitrile rubber end seals.

Particularly effective for high loads and long stroke applications.

Linear Ball Bushings

Applications

- Computers and peripheral equipment.

- Recording equipment.

- Linear motion systems.

- Multi-axis drilling machine.

- Printing machines.

- Food packaging machines.

- Punching presses.

- Tool grinders.

- Assembly systems.

- Card selectors.

Interchangeability

Our linear bushing systems are designed to have full interchangeability, with other manufacturers’ parts. For shafting see part numbers L1770 to L1785.

High precision retainer

The single body retainer guides 4-6 ball circuits. It precisely guides the balls with a smooth motion.

Tolerance of housing bore

Normal fit is standard, pressed fit is for without clearance.

Part no. | Normal fit | Pressed fit |

| L1706 to L1733 | H7 | K6, J6 |

| L1706...-1 to L1733...-1 | H7 | J7 |

Rigid outer sleeve

The hardened and precisely ground outer sleeve is made of bearing steel.

L1750 bushing carriages

Consists of light aluminium case and L1706 type linear bushing, so the installation can be finished simply by bolting. Longer life can be obtained by adjusting the orientation of the ball circuits in the linear carriage element against the direction of load.

Tolerance of shaft

Part no. | Normal fit | Tight fit |

| L1706 to L1733 | h6 | k6 |

| L1706...-1 to L1733...-1 | f6, g6 | h6 |

Basic dynamic load rating C

The basic dynamic load rating is defined as the constant load both in direction and magnitude under which a group of identical linear bushings are individually operated. 90% of the units can travel 50Km without failing due to rolling contact fatigue.

Basic static load rating C0

If a linear bushing is subject to an excessive load or impact, a permanent deformation occurs between the raceway and the rolling element. The basic static load rating is defined as the static load that gives a prescribed constant contact stress at the centre of the contact area between the rolling element and raceway receiving the maximum load.

Superball linear ball bushings

- 3 x the load rating and 27 x the travel life of conventional linear bushings

- Self-aligning feature

Self-alignment

The ball plate has a convex shape to provide a pivot point at the centre which allows self-alignment up to ±0.5°. This self-alignment capability eliminates any possibility of edge pressure caused by inaccurate machining, errors on mounting, or shaft deflection.

Tolerance of shaft and housing bore

Part no. | Shaft Ø d1 | Tol. h6 μ | Housing bore Ø d2 | Tol. H7 μ |

| L1740.010 | 10 | +0 to - 9 | 19 | +21 to -0 |

| L1740.012 | 12 | +0 to - 11 | 22 | +21 to -0 |

| L1740.016 | 16 | +0 to - 11 | 26 | +21 to -0 |

| L1740.020 | 20 | +0 to - 13 | 32 | +25 to -0 |

| L1740.025 | 25 | +0 to - 13 | 40 | +25 to -0 |

| L1740.030 | 30 | +0 to - 13 | 47 | +25 to -0 |

| L1740.040 | 40 | +0 to - 16 | 62 | +30 to -0 |

| L1740.050 | 50 | +0 to - 16 | 75 | +30 to -0 |

Features

Higher load ratings

The uniquely designed ball plate (in the outside diameter of the bushing), is made of hardened steel. The precision ground groove is slightly larger than the ball size, which provides greater contact area between the balls and the ball plate, and as a result, provides 3 x higher load ratings of conventional linear bushings.

Alexia House, Glenmore Business Park

PO19 7BJ Chichester

United Kingdom

0333 207 4498

sales@automotioncomponents.co.uk

Route via Google Maps

Company registration no: 00496138

Company VAT number GB 408154022