Linear Rails from Automotion

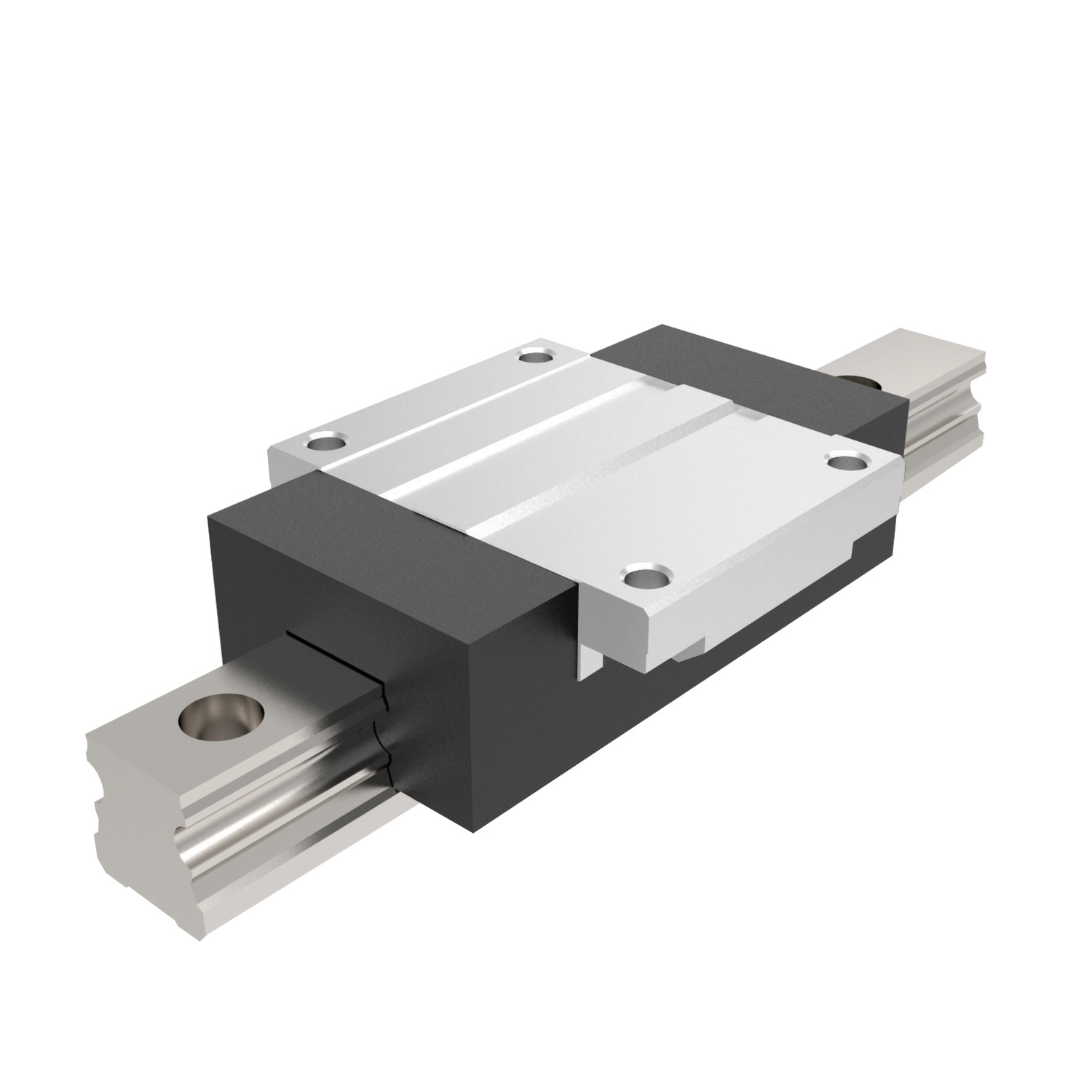

A linear guide, or linear rail, is a system which helps with the movement and supporting of the load of a piece of equipment in a linear fashion, either vertically or horizontally. We have a high load, high precision, gothic arc profile linear guide system to DIN 645 interchangeable with other major competitors systems. Miniature versions of this system are also stocked in hardened stainless steel.

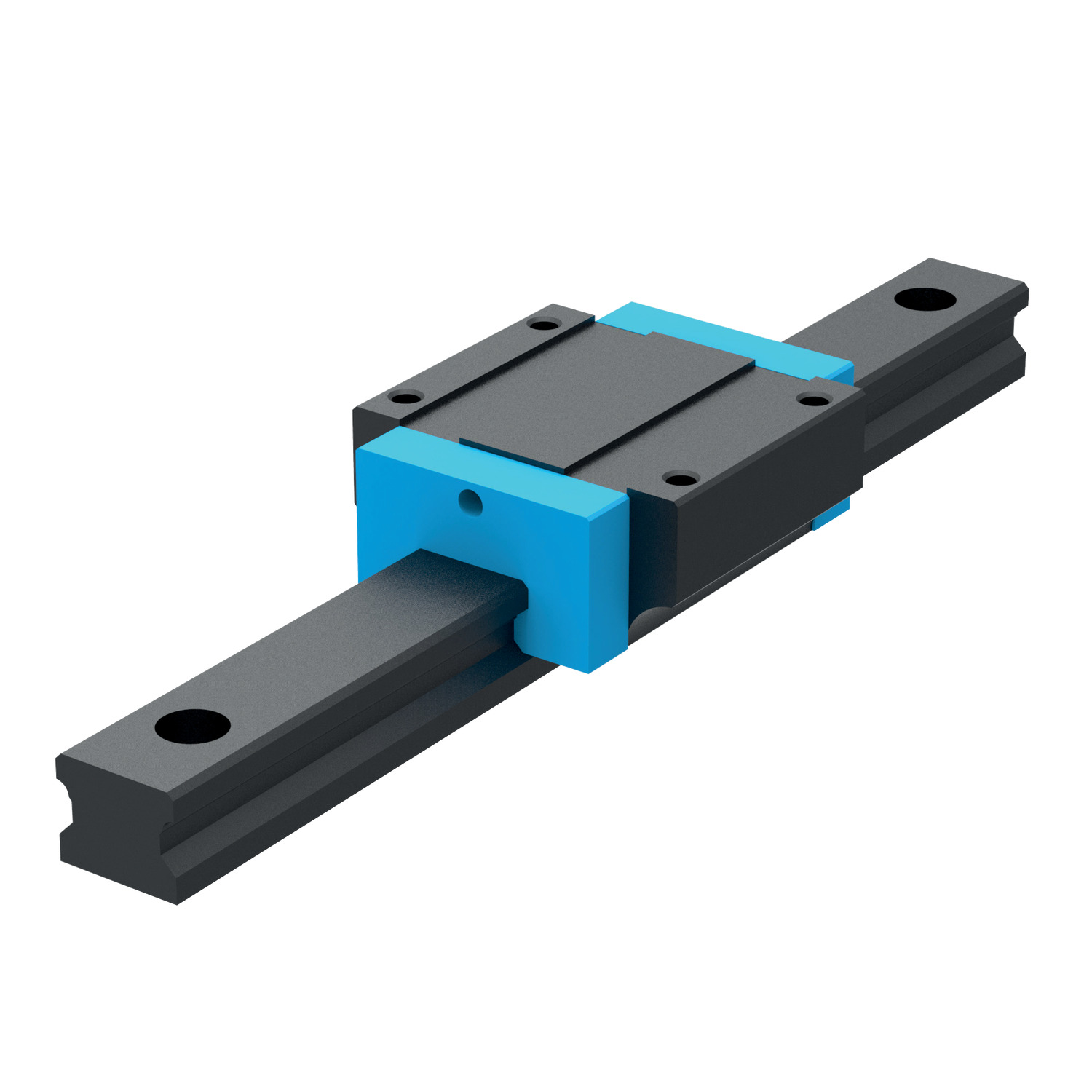

We also have roller bearing linear guides which allow for misalignment in the system when using a pair of guides, making installation quicker and more cost effective. These come in a precision range or a low cost range available in AISI 316 stainless steel, ideal for applications such as marine based ones where corrosion resistance is necessary.

Make sure you request a free Linear Motion Handbook here and utilise our free CAD to help you save time planning your projects.

Linear Rail Options

Our most popular linear rail systems with either flanged or un-flanged carriages (L1016.F or L1016.U). Width sizes 15, 20, 25, 30, 35, 45 and 55mm. Lengths up to 4 metres and rear-fixing rails also stocked (L1016.RF). Ultra-low profile carriages also available (L1016.UL).

We also stock a wide range of hardened stainless steel linear rails for applications in which space may be at a premium. Available in width sizes 5, 7, 9, 12, 15mm. Carriages (L1010.C) and clamps (L1010.CL) are also in stock.

Our anodised aluminium linear rails offer a 60% weight reduction over standard steel or stainless steel. They contain hardened stainless steel raceways for added durability. 15, 20 and 25mm versions available. Compatible with standard carriages (e.g. L1016.F) or special aluminium carriages L1018.F and L1018.U.

Blackened front fixing linear rail, comes in 15mm, 20mm & 25mm lengths. Rear-fixing versions (L1016.BR) and matching blackened carriages (L1016.F-BC and L1016.U-BC) also available.

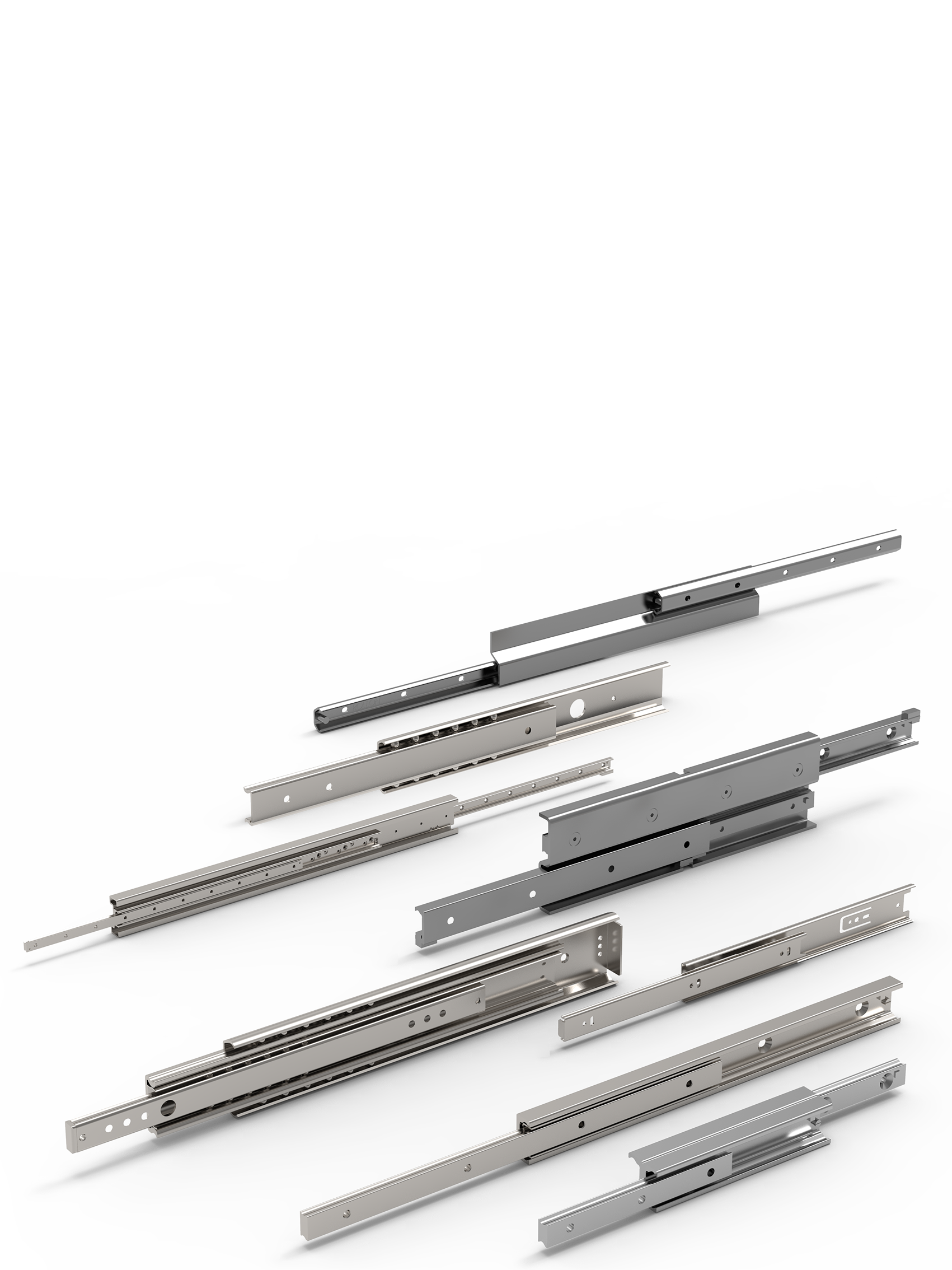

X-rails are highly cost-effective systems for linear motion. Shown here in zinc-plated steel (L1970) but also available in stainless steel (L1971) for added corrosion resistance. For more information, see our X-rail technical page or our catalogue. Excellent for applications such as drawers, protective screens, battery casings etc

Low cost AISI 316 stainless steel rail system suitable for outside and marine environments. Stainless steel (A4, 316L) rail systems (L1971) can be used in wet or corrosive environments (including sea water).

Needle roller rail systems are made from hardened and ground steel. They are suitable for heavy duty needle roller carriages L1017.U (unflanged) and L1017.F (flanged).

Crossed roller rails, or crossed roller bearings are low profile, high precision rail sets.

Carriages for linear rail shafts with supports. Available in many configurations.

Hardened steel linear rail shafts with h6 standard tolerance. Special tolerances by request. 5 - 60mm diameter.

Stainless steel rail shafts for linear motion. Hardened, corrosion resistant stainless steel (440C).

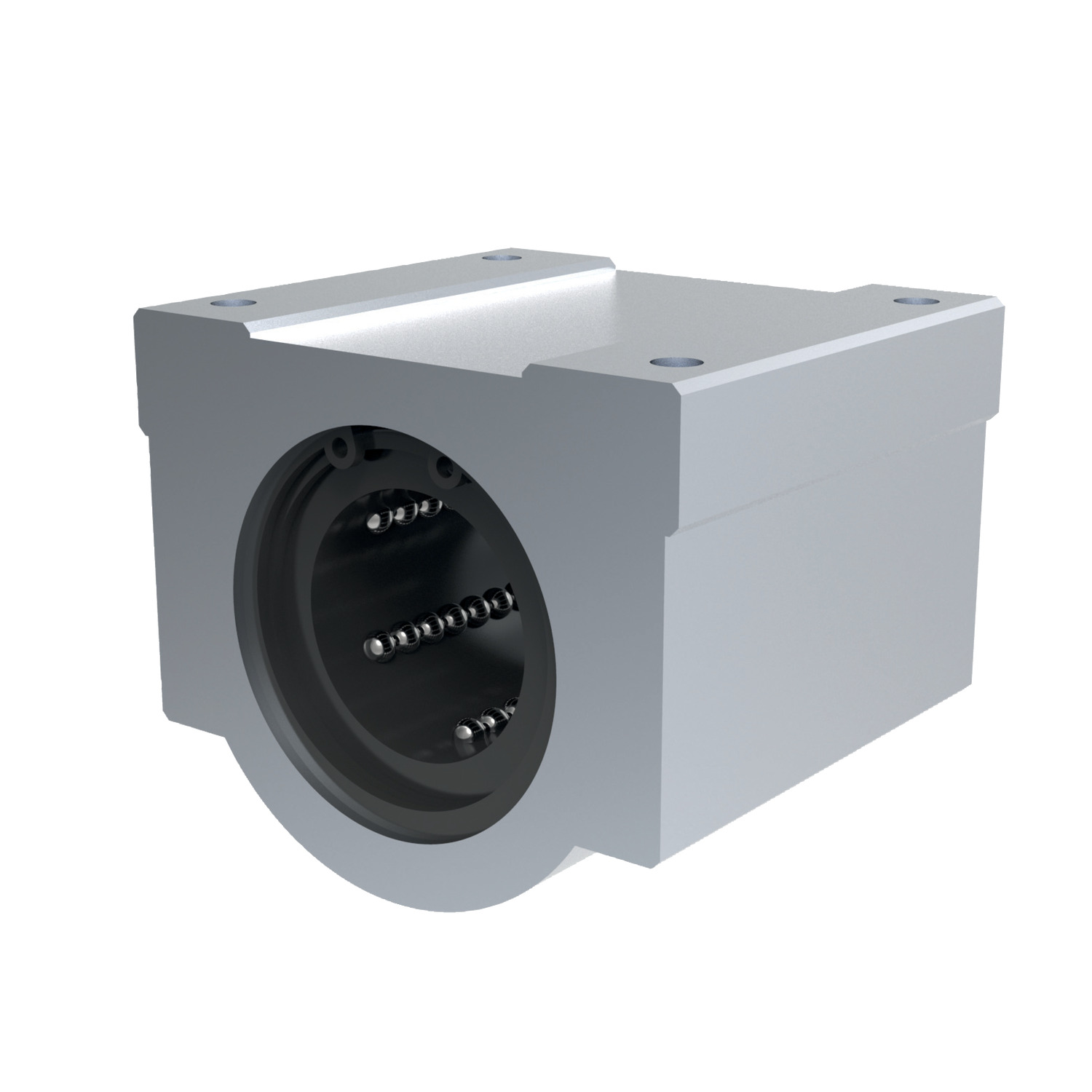

Linear ball bushings held captive within an aluminium housing for easy installation.

Linear ball bushings for use with linear rail shafts. Open, closed or adjustable versions in stock. Superball variation with higher load rating and longer service life also available.

Linear ball bushings with either a square of circular flange to aid installation.

Curvilinear motion can be achieved with our curved rails. Dimensions arranged by request. Can be produced in zinc-plated steel or stainless steel. Constant radius curved rails also available (L1978.CR).

Easy slide high-load rails come in sizes 28, 35, 43 or 63. They are made from zinc-plated steel with induction-hardened steel raceways.

Associated Products

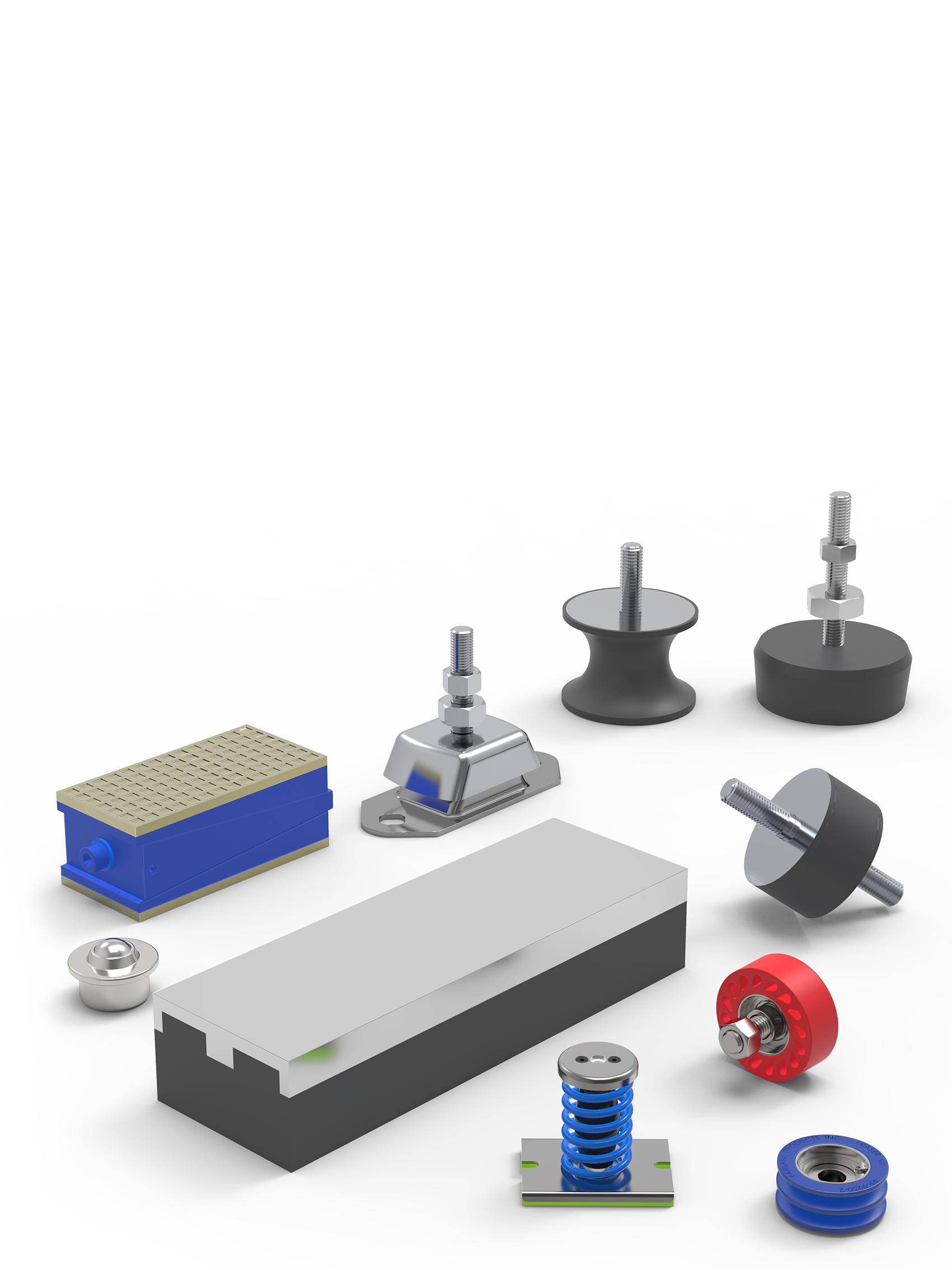

When used with the corresponding V rail, and rollers, these roller rails can provide linear motion and support heavy duty loads.

Linear tables (in steel or lightweight aluminium) provide linear motion for light/medium loads. Heavy-duty versions also available.

Linear Rail Features

Features

L1016 Linear guideways

Linear guideways are widely used throughout industry for heavy-duty and precise applications.

Precision high load rails

The use of steel balls and the design of the carriages and guideways mean that the rails can accept very heavy loads and signifi cant moment loads. Our rails have circular as opposed to friction coefficient, lower driving resistance, lower wear and lower energy consumption.

Cost-effective

We can cross reference other manufacturers’ part numbers including THK, INA, Bosch, IKO etc.

Rigid and precise

• High load rating.

• High moment load capacity.

Stocked

7 rail profiles ready for same day despatch. Lengths up to 4 metres.

Linear Rail Product Selection

Read on below for information about linear rail sizes, carriage lenghts and rail types.

Product Selection

Rail sizes

Carriage types

Carriage lengths

Rail types

Linear Rail General Guidance

General Guidance

Load capacities – explained

• A number of load figures are stated for load capacity:

Dynamic Load – this is the main fi gure considered for linear guideways. It is the moving load that the system can bear. It takes account of the total moving load as well as considerations such as impact, vibration and fatigue.

Static Load – this is a load that is constant for an extended time (i.e. the dead load the system can bear before any movement). It can be in tension or compression.

For these linear guideways the radial and axial load capacities are the same.

Moment loads are twisting loads generated by off set loads in either X, Y or Z planes. Moment loads can be reduced by adding further carriages or rails to reduce any twisting of the carriage due to the load off set.

Straightness of rails

- The measurements of the straightness of the system are taken from the running accuracy of the sliders over the length of the rails (given in microns) – see system precision page.

- For standard accuracy this equates to around 20 microns for a metre length, increasing to 35 microns for a 4 metre length.

What lengths can be provided?

- We have standard rail lengths. These are based on the hole pitch of the rails and end machining to provide an equidistant length to the first and last hole centre.

- However we can cut the rail (from stock) to any length required – we just need to know the distance required to the first hole.

- In general our cutting procedures allow for a ±2mm accuracy on the overall rail length. If greater accuracy than this is required then we have to machine the end accurately (rather than cut it) and this involves extra time and cost.

- Standard maximum length for each rail size is around 4 metres. Rails can be joined together but the preparation needs to be made in our workshop. The rails will be marked clearly with the ends to be placed adjacent to each other.

Installation

- The linear guideways are very accurate and as a result need to be installed on accurately prepared surfaces – please see installation instructions. If the two rails are installed parallel to each other, they need to be accurately aligned – see assembly precision page.

- If you are not able to prepare the surface as accurately as required you might want to consider using our Compact Rail system, as this has a master rail (T rail) and a slave rail (U rail) that allows for structural inaccuracies.

Mounting the carriages to the rails

- In general the carriages will be supplied separately to the rails. To install the carriage onto the rails, offer the carriage up to the rails and slide it onto the rail itself.

New ball chain technology

Our new and improved linear guideway systems include the latest “ball chain” technology with the following benefits:

- Higher maximum velocity.

- Lower heat generation

- Lower noise generation.

- Very smooth running.

- Optimised lubrication system

- Even load distribution

- Longer service life

The rotating balls in conventional profile rail guides have point contact between each other. The rotation speed at the contact point is double the speed of the balls. The contact area (A) is so small that the surface pressure (P) tends towards infinity. This leads to heating and wear of the balls and the linear guide system.

The chain system in our new linear guides have a relatively large contact area (A), this significantly reduces the surface area pressure (P). The rotation speeds at the contact surfaces of ball and chain are the same. The ball chain is used to transport the lubricant and to create a lubrication film on the balls. The design of the carriage allows effective supply of lubricant from the lubricant connection to the circulation areas of the ball chains.

This design of the of the ball chain ends in connection with the spacer ball closes the circulation and makes the movement of the carriage smooth and quiet.

New technology

It is not possible to keep the distance of the balls (C1, C2) constant in conventional linear guides. These irregular distances between the balls lead to uneven running behaviour.

The new ball chain system also allows the balls to be continuously supplied with lubricant, which reduces wear of the metal. This significantly extends the service life of the system and reduces lubricant and the maintenance intervals.

We can coat our rail with a type of corrosion protective finish:

- Raydent coating; this is an electro-chemical process that applies a black oxide-ceramic layer (approx. 1 micron thick) that penetrates into the metal. As coating takes place at OC the parts are not deformed. Good resistance against acids, bases and solvents.

Where there may be a high level of dust, dirt, weld splatters etc. we can provide bellows covers to protect the rails.

Linear Rail Technical Specs

How to Install Linear Rails

FAQs

Linear Rails vs Linear Rods: Which are better?

Linear rails and linear rods (or linear shafts as they are known in the industry) both perform similar functions however there are subtle differences. Owing to its high rigidity, linear rails have much less flex and can support heavier loads. Linear rails also provide a more stable platform when compared to linear rods, preventing rotation and providing more accurate and steady results. Conversely, linear shafts are typically a more cost effective solution and are easier to manufacture in custom configurations to suit any application.

What is a Linear Rail used for?

Linear reails are utilized in a variety of diffirent industries and are used for moving items through a production process with great precision and minimal friction. If you require a system that’s suitable for applications that require high precision, a long life and high rigidity then linear rails provide the perfect solution. Linear rails are available in a variety of sizes, preloads and accuracy classes.

Can Linear Rails be used sideways?

Linear rails are designed to support the movement and load of a piece of equipment in a linear fashion, either horizontally or vertically. Highly precise and extremely rigid, linear rails are also designed to withstand downward loads, lift-off loads and moment loads. If you require technical help or support please get in touch with Automotion Components today.

Alexia House, Glenmore Business Park

PO19 7BJ Chichester

United Kingdom

0333 207 4498

sales@automotioncomponents.co.uk

Route via Google Maps

Company registration no: 00496138

Company VAT number GB 408154022