Mission-Critical Precision Engineering for the UK Defence Sector

Trusted by defence contractors and OEMs to deliver Precision components that meet the strictest Ministry of Defence standards.

In defence operations, reliability is everything.

Precision-engineered components are the backbone of military vehicles and equipment, built to endure extreme conditions and deliver uncompromising performance.

From engine parts to complex systems, every detail is crafted to keep our armed forces mission-ready.

Book a Confidential Consultation with Our Defence Engineering Team

Whether you're scaling production or solving critical supply chain challenges, our engineers are ready to support your next mission.

Why Choose our Defence Fasteners?

- High-performance materials: PEEK, stainless steel, corrosion-resistant metals.

- Lightweight & durable designs optimised for defence applications.

- Reliable under extreme conditions: vibration, shock, chemical exposure, and temperature extremes.

- Comprehensive range: screws, washers, nuts, mounts, rails, and joints for land, sea, and air systems.

- Browse our full catalogue to upgrade your defence system with proven, reliable fastening solutions.

Trusted by defence contractors and OEMs to deliver Precision components that meet the strictest Ministry of Defence standards.

In defence operations, reliability is everything.

Precision-engineered components are the backbone of military vehicles and equipment, built to endure extreme conditions and deliver uncompromising performance.

From engine parts to complex systems, every detail is crafted to keep our armed forces mission-ready.

Book a Confidential Consultation with Our Defence Engineering Team

Whether you're scaling production or solving critical supply chain challenges, our engineers are ready to support your next mission.

Why Choose our Defence Fasteners?

- High-performance materials: PEEK, stainless steel, corrosion-resistant metals.

- Lightweight & durable designs optimised for defence applications.

- Reliable under extreme conditions: vibration, shock, chemical exposure, and temperature extremes.

- Comprehensive range: screws, washers, nuts, mounts, rails, and joints for land, sea, and air systems.

- Browse our full catalogue to upgrade your defence system with proven, reliable fastening solutions.

Engineering Challenges that Demand Absolute Precision

Designing for the defence sector means balancing strict tolerances, complex geometries, and uncompromising compliance. Small deviations can result in system failure. Delays can stall production.

That’s why engineers rely on proven suppliers with the capability to manufacture to spec — every time.

- ✅ Superior reliability in demanding environments

- ✅ Reduced wear and extended equipment lifespan

- ✅ Lower maintenance costs and downtime

- ✅ Enhanced safety and mission success

Engineering Challenges that Demand Absolute Precision

Designing for the defence sector means balancing strict tolerances, complex geometries, and uncompromising compliance. Small deviations can result in system failure. Delays can stall production.

That’s why engineers rely on proven suppliers with the capability to manufacture to spec — every time.

- ✅ Superior reliability in demanding environments

- ✅ Reduced wear and extended equipment lifespan

- ✅ Lower maintenance costs and downtime

- ✅ Enhanced safety and mission success

Specialist Components for High-Stake Defence Applications

We design and manufacture precision-engineered components that perform flawlessly in the harshest conditions. Every part we deliver is backed by full traceability, rigorous testing, and decades of experience supporting the UK's most demanding defence programmes.

- ✅ 100% component traceability from raw material to delivery.

- ✅ Rapid prototyping with scalable production.

- ✅ Rigid quality assurance and performance testing.

Specialist Components for High-Stake Defence Applications

We design and manufacture precision-engineered components that perform flawlessly in the harshest conditions. Every part we deliver is backed by full traceability, rigorous testing, and decades of experience supporting the UK's most demanding defence programmes.

- ✅ 100% component traceability from raw material to delivery.

- ✅ Rapid prototyping with scalable production.

- ✅ Rigid quality assurance and performance testing.

Engineered for Land, Air, and Sea Platforms

We supply precision components for :

- Aircraft

- Ground Vehicles

- Missiles

- Ships

- Drones

- Ground Systems

- Field Equipment

- Submarines

- Radar & Comms

- ISR Equipment

Engineered for Land, Air, and Sea Platforms

We supply precision components for :

- Aircraft

- Ground Vehicles

- Missiles

- Ships

- Drones

- Ground Systems

- Field Equipment

- Submarines

- Radar & Comms

- ISR Equipment

Engineered for Land, Air, and Sea Platforms

We supply precision components for :

- Aircraft

- Ground Vehicles

- Missiles

- Ships

- Drones

- Ground Systems

- Field Equipment

- Submarines

- Radar & Comms

- ISR Equipment

High-Performance Defence Components

PEEK Components for Defence Applications

PEEK (Polyetheretherketone) components provide lightweight, high-strength fastening solutions for defence, aerospace, and naval applications. Known for mechanical strength, chemical resistance, and thermal stability, PEEK ensures reliable performance in mission-critical systems.

Unlike stainless steel or titanium, PEEK reduces weight without compromising durability, maintaining structural integrity under extreme conditions.

Polyether ether ketone (PEEK). Beige.

A high performance engineering plastic known for it's durability and chemical resistance. It has excellent dimensional stability and a maximum operating temperature of 260°C.

Natural Polyether-ether-ketone (PEEK). Beige. A high performance plastic with very good durability and wear resistance. PEEK has excellent chemical resistance and performs well at temperatures up to 260°C. Tensile strength ~116N/mm².

Natural Polyether-ether-ketone (PEEK). Beige. High performance plastic with great durability and wear resistance. Performs well at temperatures up to 260°C and has excellent chemical resistance. Tensile strength ~116N/mm².

Natural Polyether-ether-ketone (PEEK). Beige. Tensile strength ~116N/mm². High performance plastic with great durability and wear resistance. Performs well at temperatures up to 260°C and has excellent chemical resistance.

Defence Sealing Screws

Our defence sealing screws offer secure fastening with airtight and watertight protection for military vehicles, aircraft, naval systems, and electronics. Resistant to vibration, shock, chemicals, and temperature extremes, they reduce weight and simplify assembly while protecting critical systems. Explore our range of sealing screws, washers, and nuts—available online or in our free catalogue.

Our range of pan head seal screws come with Phillips, torx and slotted drives. Ranging from M 2 to M 10, in stainless steel and with a silicone 'O'ring as standard. Other 'O' ring materials available. These are reusable screws.

These stainless steel cap head seal screws (AISI 303 1.4305 tensile strength 550 N/mm2 or AISI 316 1.440 tensile strength 480 N/mm2), with silicone 'O' ring as standard are available in either torx or hex head socket varieties.

Our countersunk seal screws with silicone 'O' ring come in Stainless steel with tensile strength 550 N/mm2. These are re-usable screws and clearance holes recommended for maximum sealing. Range between M 3 and M 10.

Automotion Components Sealing nuts & washers are re-usable and seal substances in and contaminants out.

Choose from Integral seal hex nuts and domed nuts, seal washers and waterproof seal washers. Ranging from M 2 to M 16 in A2 and A4 Stainless steel.

Captive Screws

Captive screws remain attached to panels or assemblies, preventing lost hardware during maintenance or in the field. Ideal for aerospace, naval, and military applications, they provide durability, chemical resistance, and lightweight performance. Available in AISI 303 and 316 stainless steel, these screws simplify maintenance, enhance safety, and ensure operational reliability. Complement your assembly with captive washers, retaining flanges, and installation tools.

For more information about how captive screws work, please visit our videos section for a captive screw demonstration video.

Automotion stainless Captive Screws are a specialist fastener that is retained within a target assembly or housing, typically with an unthreaded portion below the head, called a reduced shank.

Available in torx, hex, slot and Phillips drive. Ranging from M 2.5 to M 20, in stainless 303 and 316.

For an aesthetically-pleasing finish to go with dark panels requiring captive screws, our black captive screws are the ideal fasteners. The black oxide layer also provides another form of defence against corrosive environments. Available in torx, hex, slot and Phillips drive. Ranging from M 2.5 to M20, in stainless 303 and 316.

With the large head, a thumb screw offers easier grip, and the ability to tighten and un-tighten by hand. Available with slot drive or no drive, in 303 and 316 stainless steel, blackened stainless, and titanium.

Captive washers are used for added security when installing captive screws on non-threaded panels. They can be used on panels of any thickness, so long as the unthreaded portion of the captive screw is longer than the panel width plus washer thickness.

Low Head Screws

For tight assemblies and confined spaces, low head screws deliver compact, high-strength fastening. Made from PEEK or corrosion-resistant metals, they combine chemical resistance, thermal stability, and lightweight design. Ideal for military vehicles, aerospace systems, naval platforms, and electronics, low head screws improve assembly efficiency and system reliability.

A2 Stainless steel. M 3 to M 24. To DIN 7984. For the majority of screw lengths the thread goes all the way to the end of the screw (i.e. l1 = l2). For longer lengths screws the threaded portion is l2.

A4 Stainless steel. To DIN 14580. M 5 to M 8. For the majority of screw lengths the threads goes all the way to the head of the screw (i.e. l1= l2).

For longer length screws the threaded portion is l2 .

Stainless steel, high precision lead screws. We are able to provide a wide range of diameters from 4 - 20mm. Screw only.

Stainless steel (AISI 303) with black oxide coating. Ultra low head is extremely low profile. They do not require a countersunk location hole. Most suitable for machine and equipment applications with minimal clearance.

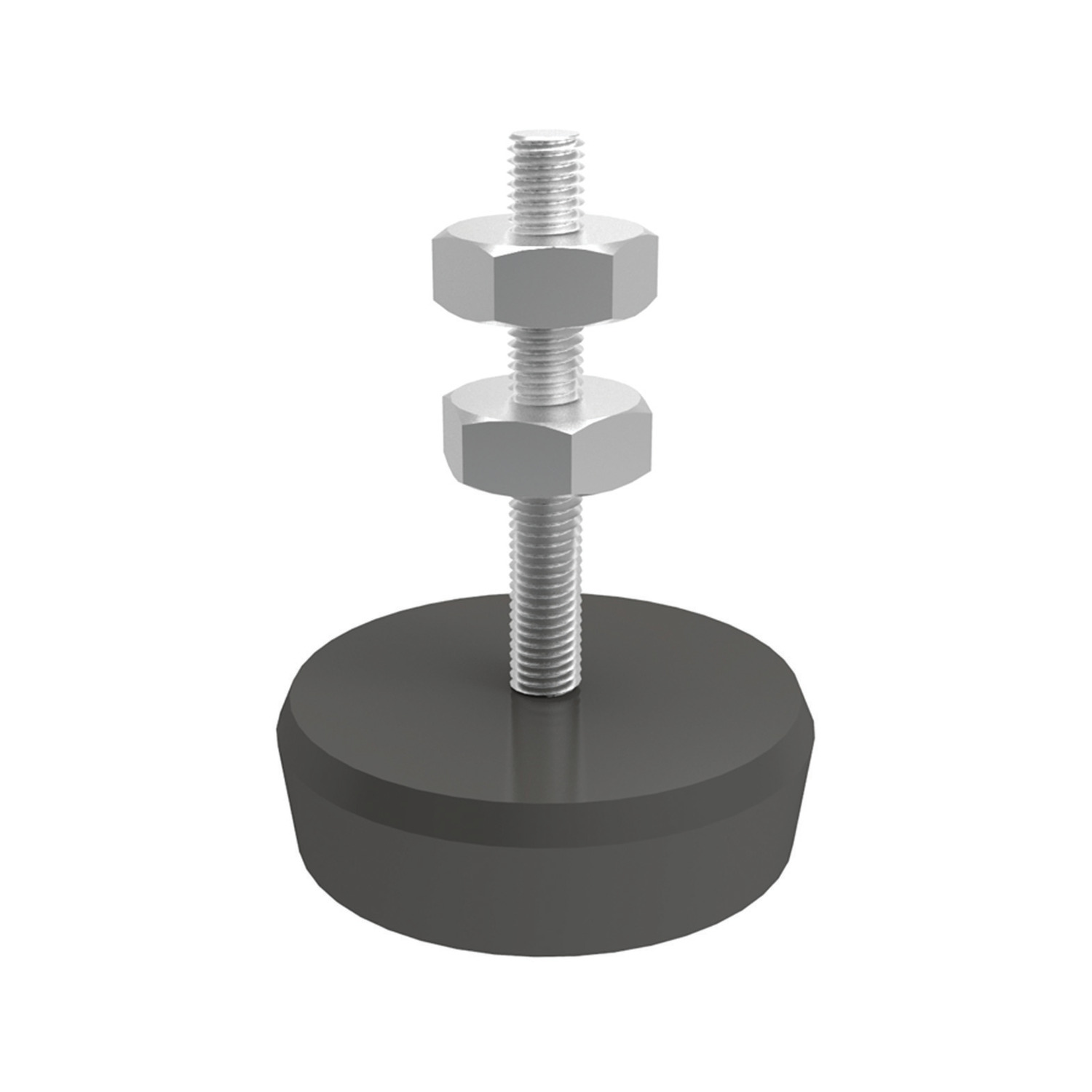

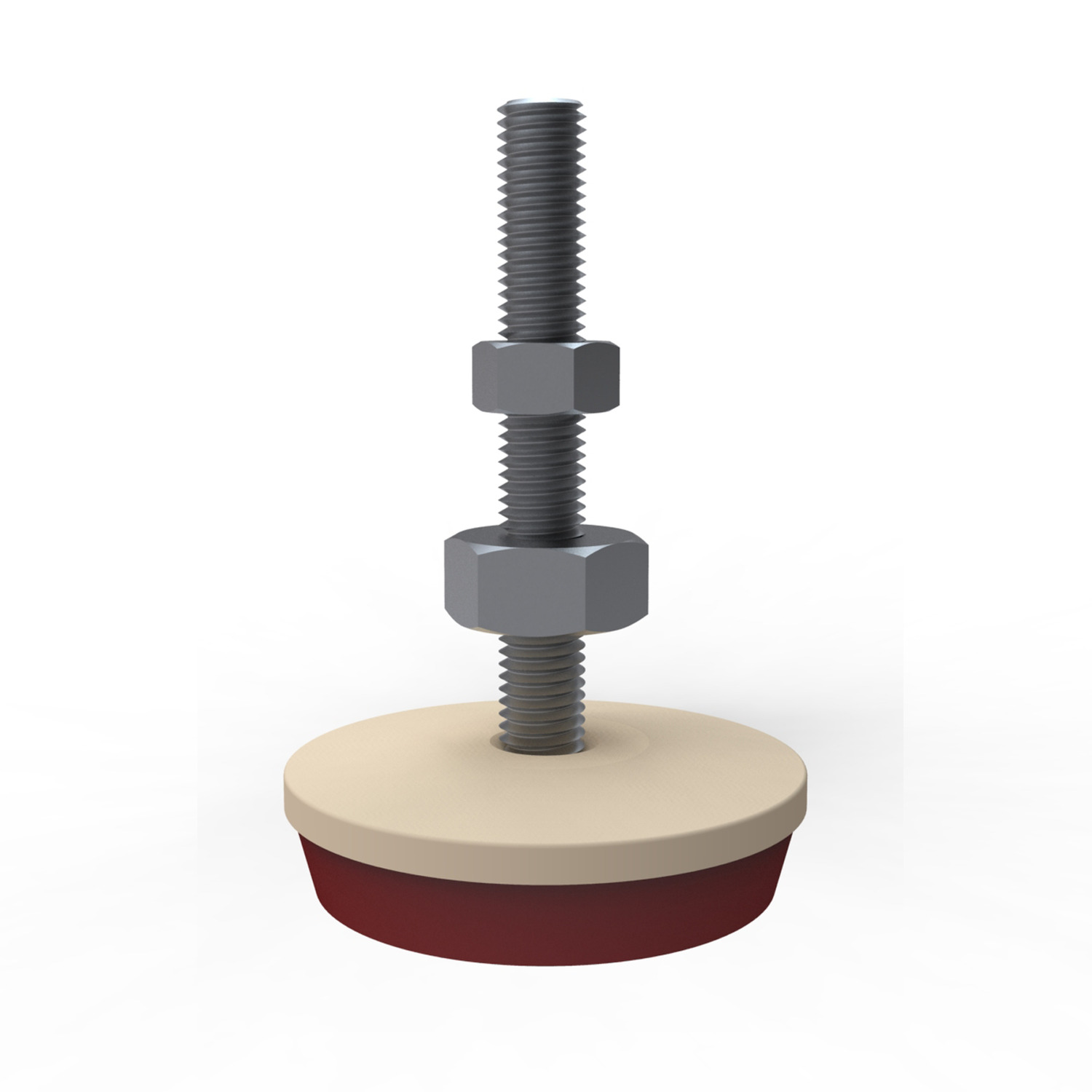

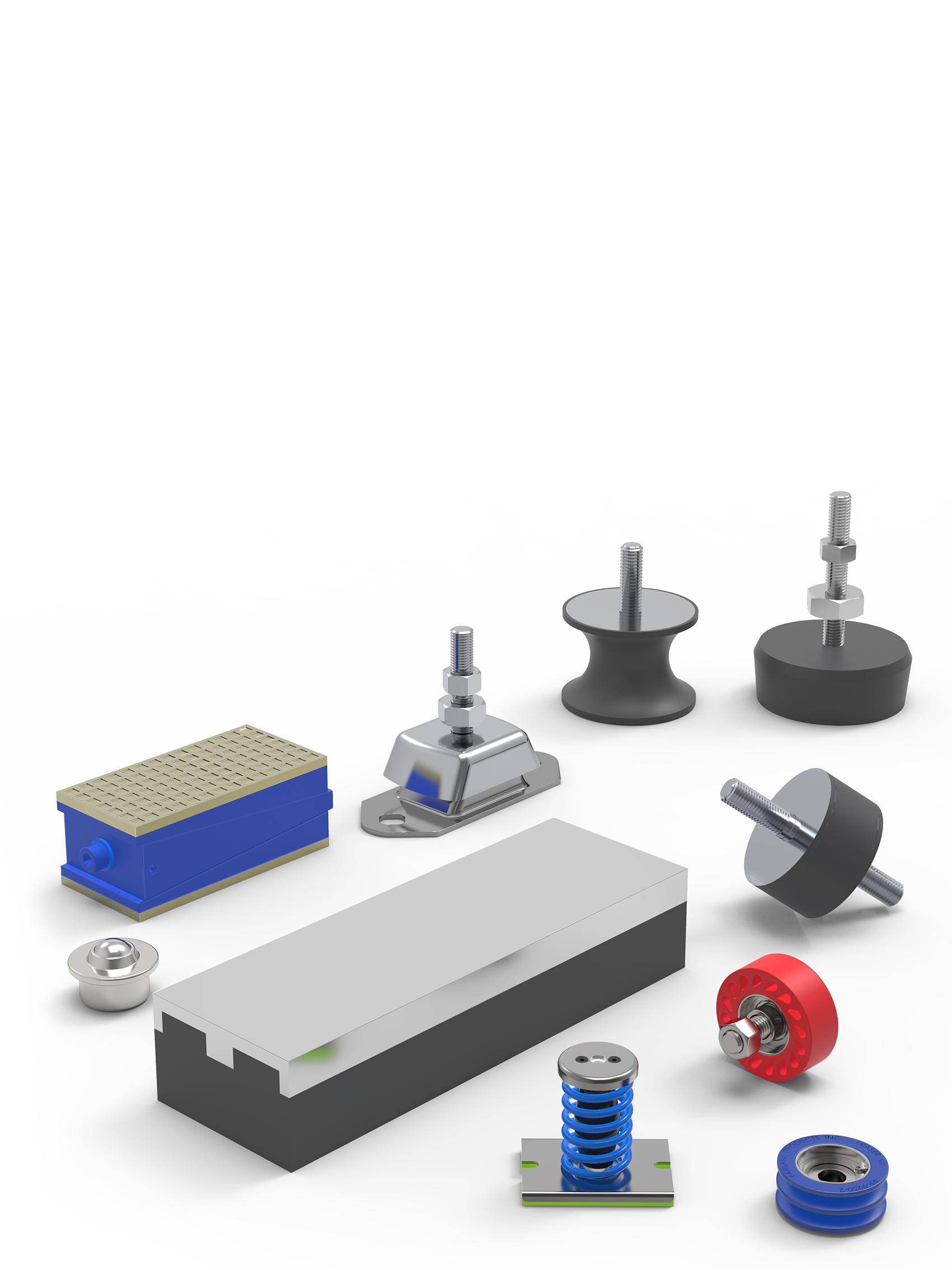

Machine Mounts & Anti-Vibration Cylinders

Machine mounts and anti-vibration cylinders protect defence equipment by absorbing shock, reducing vibration, and extending component lifespan. Made from rubber composites or corrosion-resistant metals, they deliver durability and lightweight strength. Perfect for military vehicles, naval systems, aerospace platforms, and electronics, these components enhance safety, performance, and operational reliability.

Steel body with silver zinc plated thread. Synthetic rubber pad (65-70 Shore A) with anti-slide cavity. Suitable for machinery with low frequency vibrations and for irregular floors.

Steel (GGG-40) coated body with zinc plated thread. Polyurethane base (65-90 Shore A). High resistance machine mounts, little deflection and maximum adherence due to shape of base. Resistant to water, oil, high and low temperatures, abrasions and shocks.

Galvanized steel, with rubber pad (90 Shore A). Provides great levelling accuracy with its fine pitch thread. Can take very high horizontal loads. Suitable for heavy machinery with strong vibration/impacts, such as plastic injection moulding machines, presses, guillotines etc.

Stainless steel body and thread (A2, AISI 3024) with rubber base (65 Shore A). Suitable for medium and high frequency vibrations and with smooth floors.

P2008 Cylinder.

Rubber on silver zinc plated steel (rubber hardness - 55 Shore A).

P2014 Waisted Cylinder.

Rubber on silver zinc plated steel (rubber hardness - 55 Shore A).

P2016 Waisted Cylinder.

Rubber on silver zinc plated steel (rubber hardness - 55 Shore A).

Clevis Joints

Clevis joints provide secure pivoting and controlled movement in defence applications. Designed for efficient load transfer, alignment, and articulation, they maintain performance under vibration, shock, and temperature extremes.

Available in steel, stainless steel, and plastic, with thread sizes M 4–M 48. Complete your system with pins, clips, and mating pieces.

Black plastic (Igumid G). Light weight, universal corrosion resistance. High tensile strength, vibration and noise dampening. Can be used in conjunction with rod ends R3582 and R3583. Standard thread is right hand thread. For pin and clips, see R3453 and R3446.

Steel 1.0718 (11SMnPb30k), silver zinc plated. M4-M16: DIN 71 752/DIN ISO 8140. M18-M48: Similar to DIN 71 752/DIN ISO 8140 and according to CETOP standard. For left hand, see R3386.

Stainless steel 1.4305 AISI 303. M4-M16: DIN 71 752/DIN ISO 8140. M20: Similar to DIN 71 752/DIN ISO 8140 and according to CETOP standard. For left hand, see R3401. Assembly made up using R3402 clevis joint and R3438 clevis retention clip.

Stainless steel (1,4305 AISI 303). Similar to DIN 71 752/DIN ISO 8140/CETOP standard. Standard is right hand thread, (For left hand see R3417). Other Tolerances: For r1, radius or 45° bevelling.

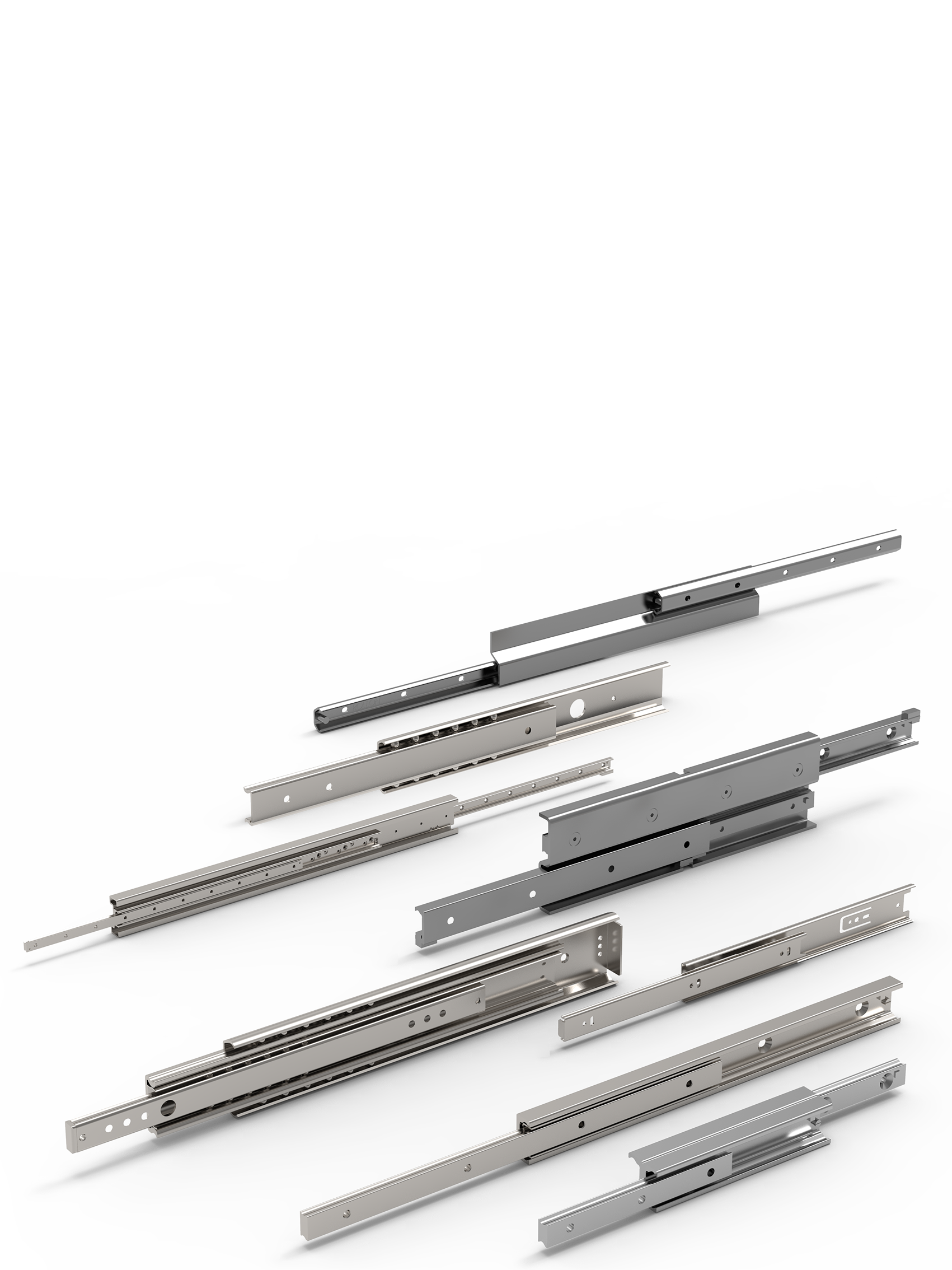

Linear Rails

Linear rails deliver precise, smooth motion for military vehicles, aerospace systems, naval equipment, and advanced weapons platforms. Built for heavy loads and extreme conditions, they maintain stability and accuracy. Manufactured from hardened, corrosion-resistant materials, linear rails withstand vibration, impact, and temperature extremes. Custom cutting and machining options are available.

The X-rail system is a cold rolled rail system offering an economical solution to simple linear movement applications. The X-rails allow some misalignment and are therefore operator friendly. Available in 3 sizes to suit less accurate engineering applications (as compared to our 'Linear Guideways' section). With lengths up to 3 metres, these X-rail linear motion systems are low-profile and very effective. For higher load capacities, see our 'Easy to Install Rails'.

Stainless steel (A4, 316L) rail systems can be used in wet or corrosive environments (including sea water). Rubber seals protect the bearings. Stainless steel X-rails are supplied in 3 sizes to suit required load ratings.

An affordable heavy duty sliding rail system with high strength and rigidity for heavy duty shorter stroke applications (lengths up to 2 metres). Only for horizontal linear translation applications. Load capacity of up to 122 kN per rail.

Two sizes of curved rail - made to suit the customer's required radius and arc length. Can be supplied with constant radius or with variable radius. Ideal for linear motion guide rail systems that need to turn corners.

Lead Screws & Ball Screws

Lead screws and ball screws enable precision linear motion and load handling for defence systems, from targeting equipment and aerospace actuators to naval machinery.

- Ball screws: energy-efficient. low maintenance, precise.

- Lead screws: robust in dusty environments, available in high-precision versions.

Both are made from high-strength materials to endure vibration, shock, and harsh conditions, ensuring mission-critical reliability.

Commercial trapezoidal lead screws and nuts (both right and left handed, or bidirectional thread), in steel and stainless steel. Diameters 10 to 120 mm, standard lengths up to 3 metres (longer on request). Also check out our lead screw accessories.

Precision lead screws in corrosion resistant A2 stainless steel (AISI 304) or lightweight aluminium with a wide range of leads and lengths up to 1 metre. Cylindrical, rectangular or anti-backlash nuts also available online. See our miniature bearing supports to complete your project.

Ball screws from 16 to 80mm diameter with a range of leads - stocked lengths up to 3 metres - normally supplied with flanged nuts or cylindrical nuts. Ball screws are highly efficient due to the recirculating ball mechanism which helps the ball nuts minimise friction against the ball screw. This can also result in a long service lifetime.

Anti-corrosion ball screws are made from induction-hardened black chrome steel which make them ideal for outdoor applications, for instance. To complement this, use our anti-corrosion ball nuts. You must still be careful not to let debris enter the recirculating ball bearings - if you are concerned about this, speak to a member of our team about whether precision lead screws could be right for you. And

Engineering Excellence Since 1952 - Proudly UK-Based

With decades of experience in precision engineering, we’re proud to support the UK defence industry with cutting-edge components manufactured in our state-of-the-art facilities. Our team of expert engineers, machinists, and quality specialists are dedicated to one mission: delivering flawless parts that keep Britain’s defence capability moving.

Alexia House, Glenmore Business Park

PO19 7BJ Chichester

United Kingdom

0333 207 4498

sales@automotioncomponents.co.uk

Route via Google Maps

Company registration no: 00496138

Company VAT number GB 408154022