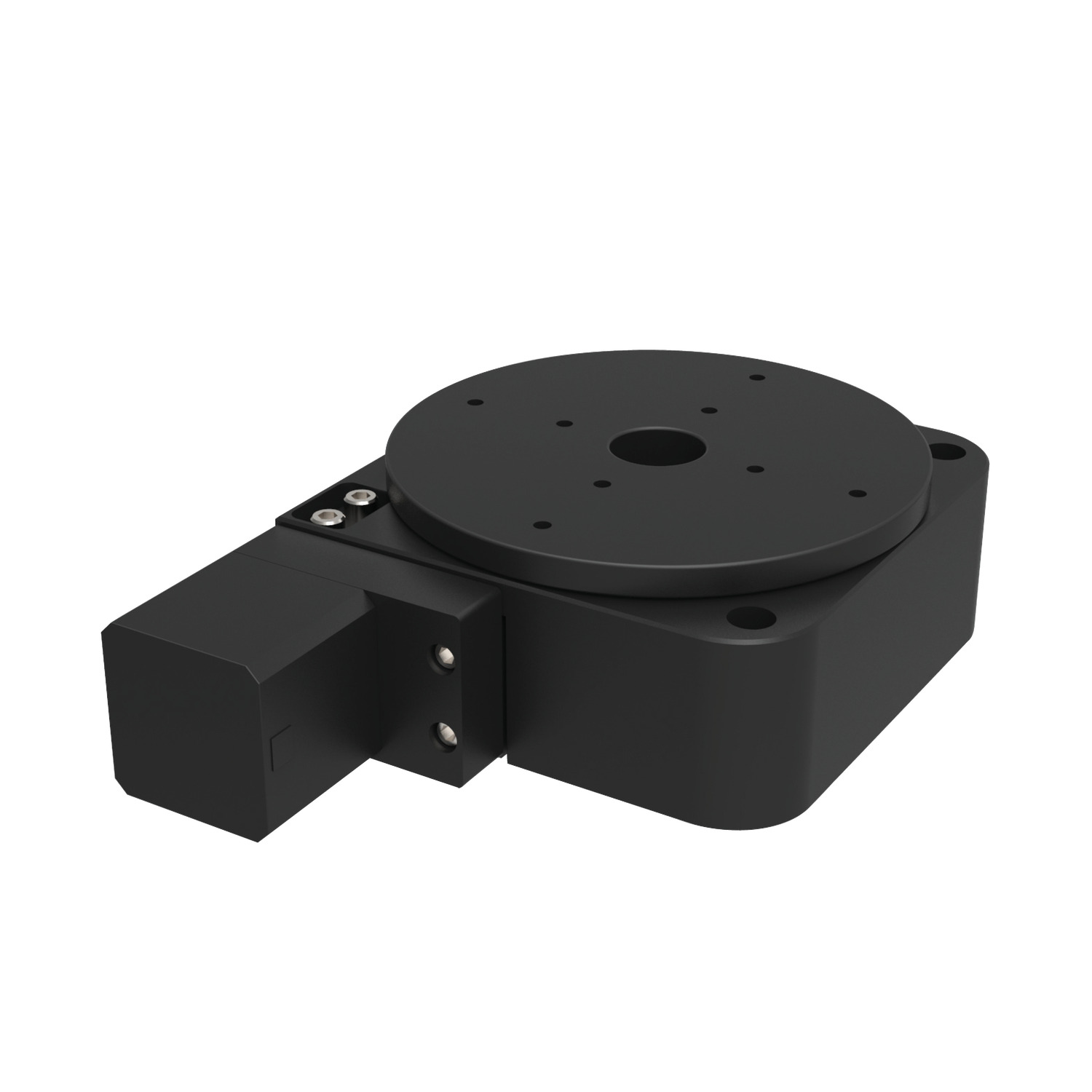

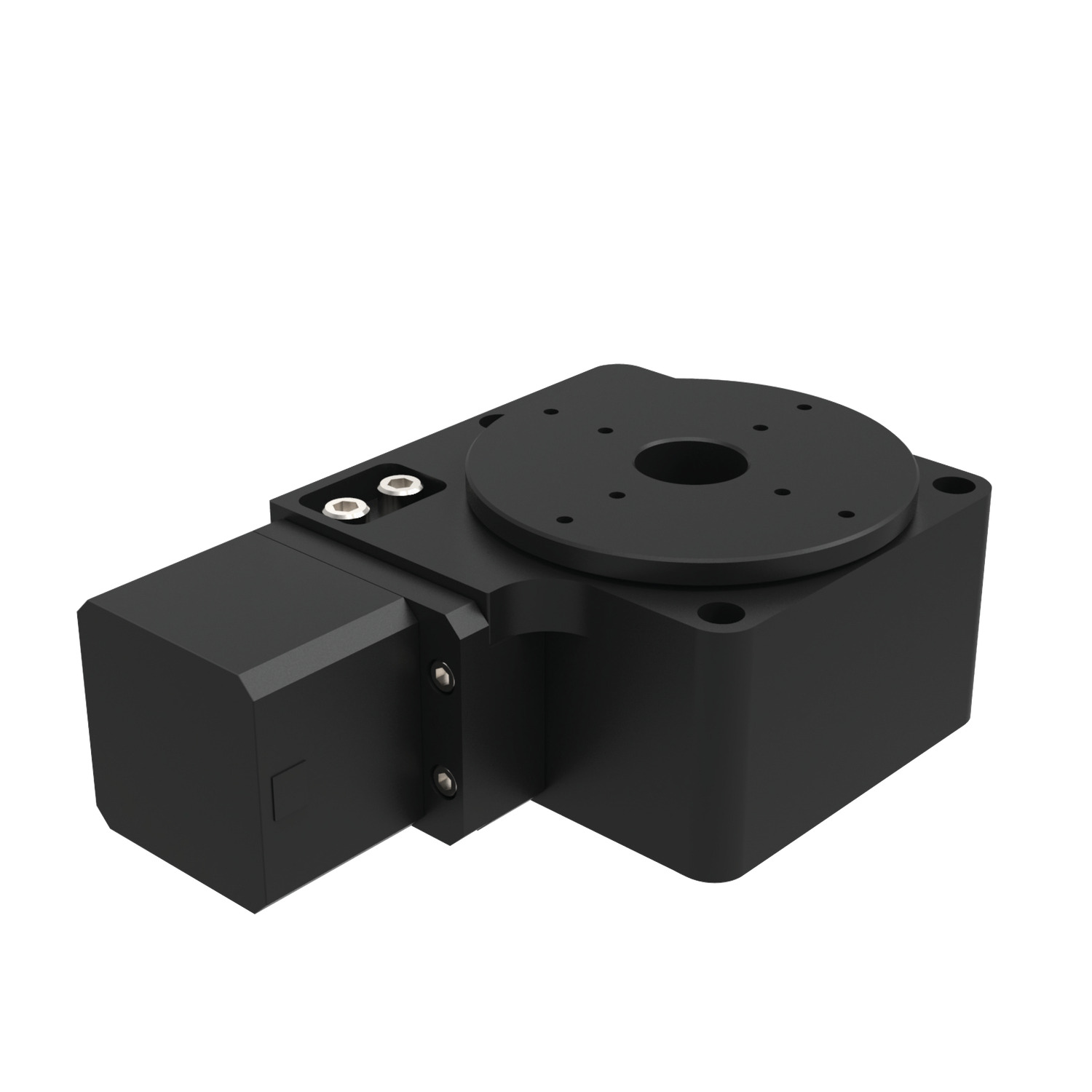

L3556 Motorised Rotary Stage Ø125

high precision, medium duty, material: Aluminium

Need more? Please call us.

| Units | Price/unit after discount | Applied Discount |

| 1-1 | £ 4,262.54 | 0% |

| 2-4 | £ 4,049.41 | 5% |

| 5+ | £ 3,836.29 | 10% |

Technical & Application

Material

Aluminium alloy body (light, stiff and stable), black anodised.

Weight 2,3 Kg.

Technical Notes

The design utilises a thrust bearing system for the table movement. This offers excellent stability at low cost, but as a result, is not really suitable for use in a vertical application. For vertical applications see L3254 and L3258 - L3262.

Easy plug and play system. Controllable from PC or PLC when used in conjunction with a motion controller. Controllers come with their own software but you can also use your own pre-existing software with them such as Labview etc.

Integrated stepper motor has a motion controller built into it.

The stages are offered with different gear ratio options. A proprietary preload system ensures zero backlash in the gear train.

The travel is 360° continuous.

Easy to use plug and play system when used with a motion controller. Can be used in conjunction with motorised linear stages for multi axis applications.

Tips

Requires external home switch (if required).

Motor options:

Stepper - Nema 17, high torque, brushless. 0.95 Amp/phase, 5.0 Ohm/phase, 3.1 mH/phase, 1.8°/step. Optionally with home switch and 1000 line rotary encoder.

Intelligent stepper - Nema 17 with a fully programmable motion controller inbuilt (i.e. no need for an external motion controller). Two +5 to +24VDC I/O lines. One 10 bit analogue input selectable 0 to +10VDC, 0 to +5VDC. RS422/485 communications. Input voltage +24VDC. Optionally with home switch and 512 line rotary encoder.

Drawings show stepper motor configuration. See special pages for further motor options.

Product Datasheets

CAD files

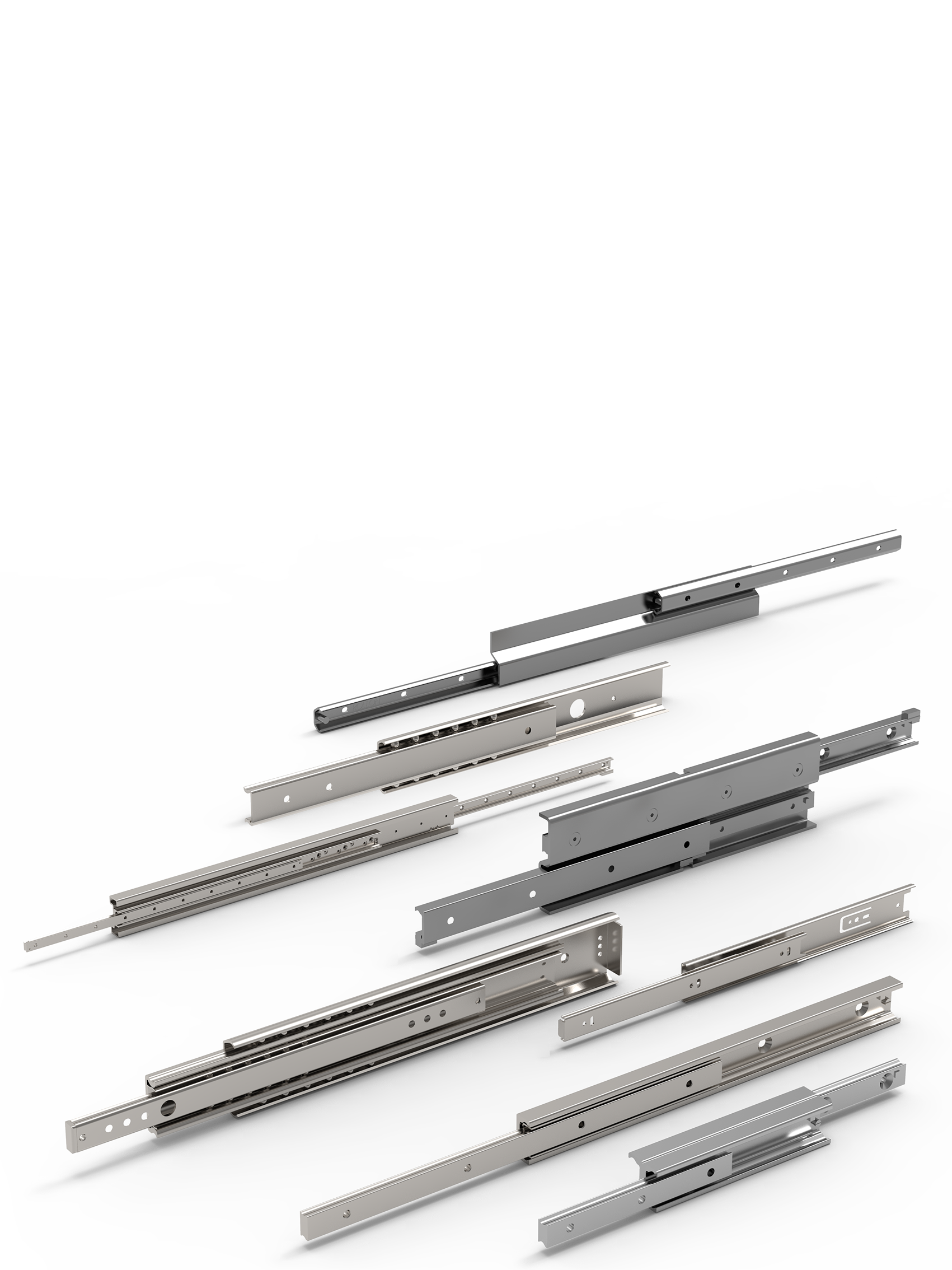

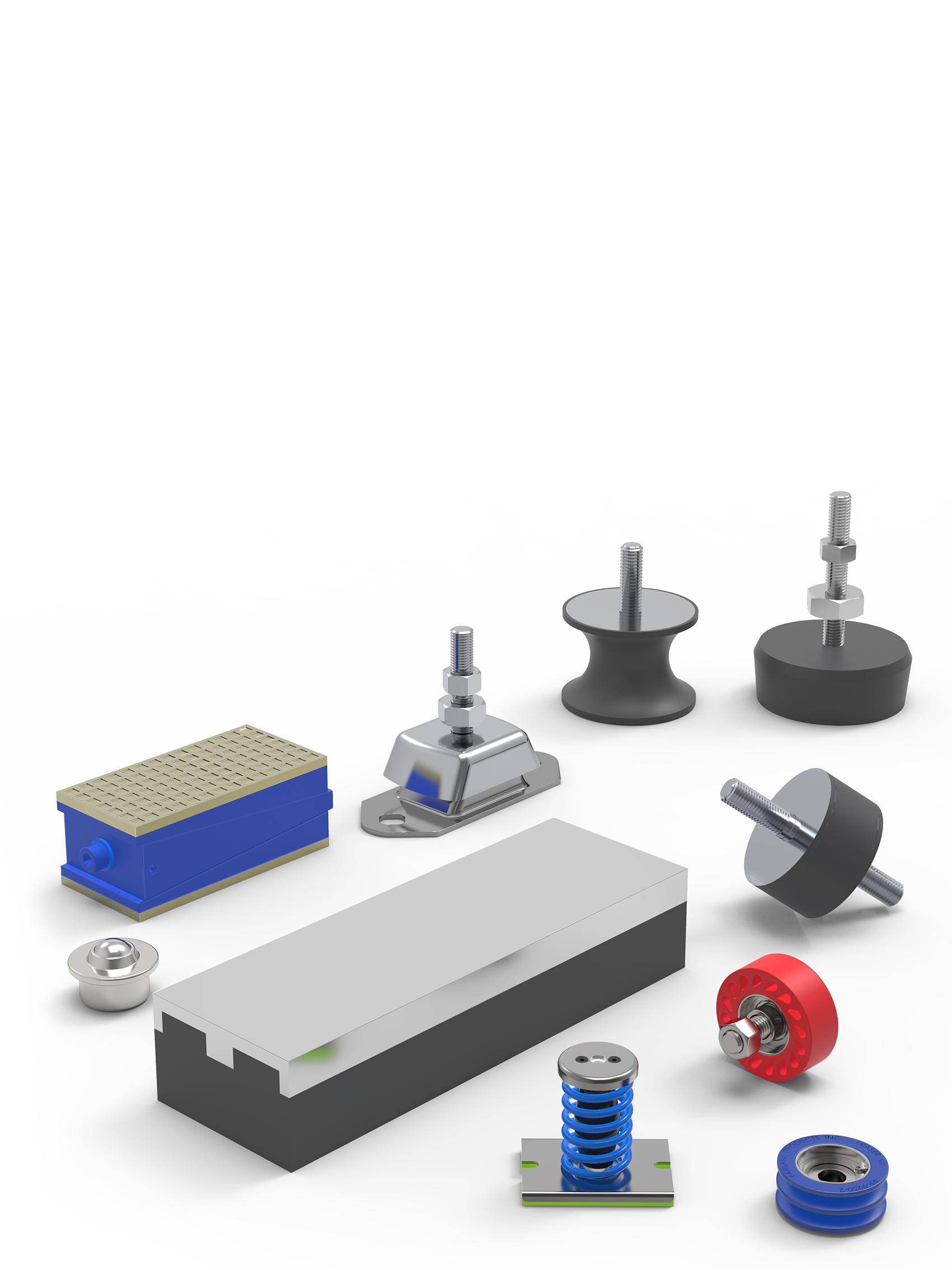

Alternative products you may wish to consider

Alexia House, Glenmore Business Park

PO19 7BJ Chichester

United Kingdom

0333 207 4498

sales@automotioncomponents.co.uk

Route via Google Maps

Company registration no: 00496138

Company VAT number GB 408154022